100% quality control

Whether you order one or twenty mobile lift tables is not crucial: Each single mobile lift table is subjected to a strict test.

Enquire about the most common variants

Get a free quote for your mobile lift table in just two steps. Feel free to note any customizations, such as a different payload or dimensions, in the 'Change requests' field.

What are mobile lift tables used for?

Mobile lift tables make the daily work with bulky goods easier. They carry out two functions at once: lifting and transporting large loads.

Although versatile in their applications, they are often utilized as mobile work lift tables. They serve either as transport aids for tools and spare parts or as welding and assembly lift tables, bringing machine components to a comfortable working height.

In terms of structure, their lifting mechanism bears some resemblance to a scissor lift truck. However, thanks to the robust scissors and the stationary chassis, our mobile lift tables can often handle higher load capacities. Therefore, they are ideal assistants for the flexible handling of larger loads.

How is the lifting motion achieved?

Our mobile lift tables can be equipped with either a manual hand pump or an electric control. The choice of the drive type depends on the price, required load capacity, necessary lifting height, and desired lifting speed.

For significant lifting heights, an electric drive is generally recommended. For smaller payloads and lower lifting heights, however, a hydraulic pump may be more practical.

We are happy to assist you in determining the best drive type for your specific requirements.

Battery operation or mains connection?

When it comes to swiftly and effortlessly lifting heavy loads to the correct height at different locations, our mobile lift tables with electro-hydraulic drive are the right choice. Compared to manually operated lift trucks, they offer the advantage of lifting or lowering the load with just the push of a button, eliminating the need for manual pumping by hand or foot. Especially in cases where the lift table is frequently used, the electro-hydraulic lifting process provides significant ease of operation and increased productivity.

The decision for an electro-hydraulic drive raises the question of whether battery or mains operation is more practical. The choice between the two variants depends on the specific use case. Here are some arguments for each operating mode:

When battery operation is useful

- The scissor lift table needs to be completely mobile without the need for a power outlet or electrical cable.

- The range of movement is extensive, meaning the lift table is frequently required at widely separated workplaces.

- Power outlets are scarce.

For battery operation, we use low-maintenance batteries that can be charged at any standard power outlet (230 V, 50 Hz). The powerful charger can be integrated directly into the lift table as needed. Alternatively, we also offer maintenance-free gel batteries.

When a mains connection is the best choice:

- The hydraulic lift table is used in a 3-shift operation that does not allow for extended charging times.

- The range of movement is limited, meaning the lift table needs to cover only a short distance.

- Sufficient power outlets are available at the deployment site.

For a mains connection, the cable can be supplied either loosely or on a self-retracting cable drum.

No matter which operating mode you ultimately choose: Our mobile lift tables with electro-hydraulic drive are easy to operate using push buttons. The control unit is attached to the push handle, allowing the platform to be comfortably raised or lowered. You can see an example in the following video:

The chassis

We tailor the chassis directly to your needs: from a lift table on wheels to a powered rail chassis with stainless steel rollers, we are pleased to offer you all possible variants.

The most commonly requested version is the manually movable lift table truck on wheels. Typically, two fixed and two swivel rollers with brakes are used. The combination of swivel and fixed rollers allows the lift table to be easily maneuvered to any workplace. Brakes on the swivel rollers ensure stability and prevent unwanted rolling. Alternatively, a version with four swivel rollers is also possible. The choice between plastic and solid rubber tires depends on the floor conditions and the load capacity of the scissor lift table. With the right configuration, loads of up to 2 tons can be manually moved, and with a non-powered rail chassis, even up to 4 tons.

For additional convenience when pushing, we recommend using a fixed or foldable push handle.

Given the diverse range of options, we are more than happy to assist you with personalized advice. We can help you find the chassis that best suits your needs. For more information, you can refer to our articles: 'Lift tables with chassis' or 'How easy is it to push a mobile lift table?'

More flexibility through extras

Due to their versatility, our mobile lift tables have become indispensable in various industries such as production, logistics, warehousing, and workshops. Whether it's loading and unloading, stocking machines, working at storage areas, or conveyor belts, our lift tables serve as valuable mobile load lifters.

As a manufacturer, we can customize the lift tables to meet your specific requirements. The functionality can be easily expanded using standardized components. For example, we can equip the lift table for use on a conveyor belt with a roller conveyor or for use as a work lift table with a tiltable platform. There is a suitable assembly for every application.

For an initial overview of the available equipment options, please visit our 'Lift table accessories' page. There, you will find information about the various extensions and customization possibilities that we offer for our lift tables.

The path to the right lift table

When reviewing a quote, one often wonders: Is this really the scissor lift platform I need? Has the provider truly understood my requirements?

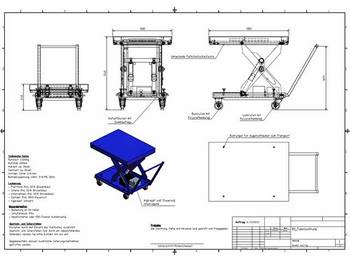

To eliminate any potential uncertainties, we follow a well-known saying: "A picture is worth a thousand words." Upon order confirmation, you will receive an approval drawing from us, encompassing all essential aspects of your order, from the actual scissor lift table to the installation situation.

Everything from a single source

We cover all phases of production for you - from the initial consultation through design and steel construction to final assembly. The advantage for you: You have a competent contact person for all questions regarding mobile lift tables.

Please feel free to call us at +49 5939 96796-90 or send an email to info@j-lifte.com if you have any questions. We look forward to hearing from you.

Frequently asked questions & our answers ...

Where is the headquarters of Janzen Lifttechnik GmbH?

We are at home in the beautiful Emsland, more precisely in Niederlangen a member community of the joint community Lathen directly on the A31 motorway. This means that we are roughly halfway between North Rhine-Westphalia and the North Sea, right on the Dutch border.

Our region is known, among other things, for the various nature reserves, the well-developed cycle paths, the manufacture of cruise ships, as well as the headquarters of various distilleries.

Should you ever come to our region, we look forward to a visit in our plant.

Where are the lift tables and lifts produced?

With us, not only does the final assembly take place in Germany, but we also cover the entire production chain from construction through steel construction to final assembly in our plant in Niederlangen. With us you get a real 'Made in Germany'.

Is the offer aimed only at traders or also at private individuals?

Even if our products are mainly used in an industrial environment, we naturally also offer them to private individuals.

Just give us a call or send us an enquiry and we will be happy to contact you.

Will I receive a drawing before production starts?

In any case. To ensure that you get the product that you really want, we provide you with an approval drawing before production begins. In addition to the actual product, this also includes the installation situation. As the saying goes, a picture is worth a thousand words.

Can I get a CAD model?

After ordering and the design phase, we are pleased to provide you with CAD models. Data exchange is possible in all common formats, including .stp, .dxf, .dwg, etc.

Where can delivery of the products be made?

We produce our lift tables and column lifts in accordance with European standards and guidelines. Accordingly, our sales area is limited to all countries that recognize these standards and guidelines (e.g. the members of the European Union, Switzerland and Australia).

For which countries is the assembly service available?

On request, we assemble our systems throughout Germany, as well as in the neighboring countries of Germany.