An alternative to mobile lift tables on wheels is the scissor lift on rails shown above...

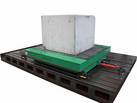

Description of application

The lift table is part of a customer's plant and is used to set up a machine. To insert the tool, the lift table must be moved by 250 mm. This horizontal movement is carried out by a cylinder on the base frame. It is guided by a rail and four polyamide sliding blocks located on the based frame. The base frame was reinforced with a bracket so that the lift table can absorb the force generated by the displacement cylinder. It is also not possible to raise or lower the lift table when it is moved horizontally. This prevents the scissor lift from colliding with the customer's plant. A built-in throttle can be used to adjust the sliding speed if necessary. Please click on the video below for a first impression of how the displacement cylinder works.

Safety equipment

The lift table is equipped with all necessary safety devices. These include, for example, the pipe rupture safety valves in the cylinder, the lowering brake valve and the pressure relief valve, maintenance supports and the all-round foot protection safety edge. Additional safety devices such as the barrier can be omitted, as the lift table is located in an area that is secured on site.

The lift table is also integrated into the customer's higher-level plant control system. A terminal strip is provided for signal exchange.