In this article we would like to clarify how high a lift table can lift. To do this, we will first take a look at the factors limiting the effective stroke. Then we will look at the correlation between platform length and effective stroke. The last section is dedicated to ways of achieving high lifting heights even when space is limited.

What limits the lifting height?

The maximum lifting height of a scissor lift table is essentially determined by two factors: the length of the platform and the load to be lifted. The correlation with the platform length will be discussed in more detail in the next section. We will first look at the load to be lifted.

A higher effective stroke in a lift table is achieved by using longer scissors. However, this has the disadvantage that the lever arms are also extended. In other words, a small lift table can lift more than a large lift table with the same cross-section of cylinder mount shafts and scissor bars.

If you now want to overcome large differences in height with higher loads, sturdier scissors must be used. If the overall height of the scissor lift and the platform dimensions are irrelevant, you could theoretically reach any desired lifting height.

The scissor length and lifting height

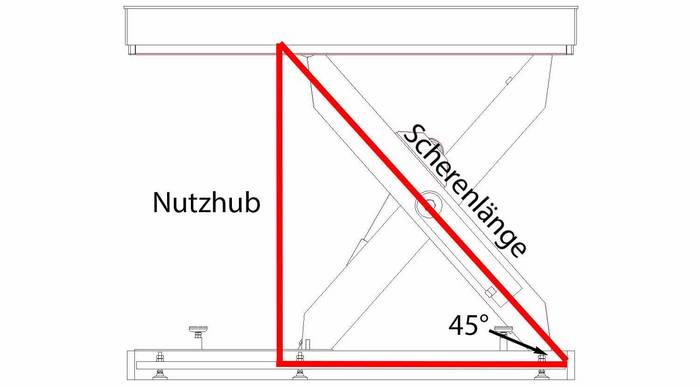

In this section we would like to show which effective stroke can be achieved with which scissor length. As a rule, the scissors of a lift table should not be set at an angle of more than 45°.

Using this information and the angle functions, it is easy to calculate which effective stroke can be achieved with a certain scissor length .

Effective stroke = scissor length * sin 45°

Effective stroke = scissor length * 0.707

Accordingly, an effective stroke of approximately 700 mm can be achieved with a scissor length of one metre.

If you now need a useful stroke of 2 metres, this formula can be easily adjusted:

Scissor length = effective stroke / 0.707

Scissor length = 2,000 mm / 0.707

Scissor length is approximately 2,830 mm

This means that the lift table must be fitted with scissors of at least 2,830 mm in length to achieve the desired effective stroke.

The minimum platform length

As you have no doubt noticed, we have so far only talked about the necessary scissor length, but we haven’t said anything about the platform length yet.

It is obvious that the platform must be longer than the length of the scissors. Accordingly, the platform length could be calculated as follows:

Platform length = scissor length + allowance

This allowance (measurement) depends on the desired equipment of the lift table. When we supply a lift table only with the standard equipment, i.e. the platform is only equipped with a foot protection safety edge and our standard limit switches, we need an allowance of approximately 150 mm. We use this space to accommodate the foot protection safety edge and our limit switches.

Standard lift table for 2 m effective stroke

Platform length = scissor length + allowance

Platform length = 2,830 mm + 150 mm

Platform length = 2,980 mm

This means that for an effective stroke of two metres, we need a platform length of at least three metres for our standard lift table .

The allowance (measurement) can be adjusted both upwards and downwards. If a foot protection safety edge is not required, the allowance can be reduced by 40 mm, for example. If additional platform installations are required, the allowance must be increased. Substructures in particular, such as a PVC roller screen as a barrier, require sufficient space underneath the lift table.

High effective stroke despite small platform dimensions

In the previous sections we have shown which platform length we need for which effective stroke. However, a long platform is not always useful or even possible. There may simply not be enough space for such a large lift table or the load to be lifted is much shorter, making a longer platform uneconomical.

In these cases, there are two possible solutions for increasing the effective stroke with the same platform dimensions:

Double-scissor lift tables

One such possibility is the use of a double-scissor lift table. In this case, two scissors are mounted vertically on top of each other. In this way, approximately twice the effective stroke is achieved with the same platform dimensions. One disadvantage of this design, however, is the higher overall height, which requires a deeper pit.

Moreover, this solution also reaches its limits at some point. Double scissors only allow a maximum of twice the stroke of single scissors to be achieved. This means that an effective stroke of about four metres would be possible with a platform length of 3 metres.

If you want to achieve even higher lifting heights, you can add to the number of vertical scissors. For example, lift table manufacturers produce lift platforms with up to five scissors arranged one above the other. Another alternative is a column lift.

Column lift

In a column lift , the effective stroke does not depend on the desired platform dimensions. This design is therefore always suitable when small platform dimensions meet high lifting heights (as is often the case with a goods lift ).

However, the disadvantage of column lifts compared to scissor lift tables is the higher costs associated with the on-site installation. While a lift table can be installed relatively quickly, the installation of a column lift is much more expensive. The installation of a column lift takes up to three times as long, whereas production is less expensive. In addition, the gantry of the column lift protrudes far beyond the highest position of the platform. Under certain circumstances, this can interfere with the look of the building.

Comments (0)

No comments found!