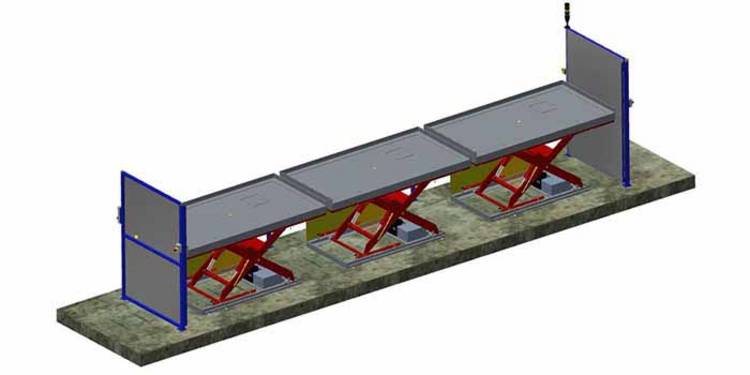

To ensure an optimal workflow in assembly line production, it is important to provide consumables at the various workplaces in the way that the sequence of work processes requires. This lift table combination of three scissor lift tables is used in the assembly of wire harnesses in an automotive plant.

Description of application

To ensure that the corresponding cable harnesses are available for assembly line production within easy reach, our customer's material is pre-picked with the help of huge compartment boxes. These compartment boxes have different levels, so that the employees often had to kneel, squat or work above shoulder height. So, a solution had to be found that would allow working at ergonomically more favourable heights: our lift table combination.

The lift tables allow the boxes to be reached in four different positions, which assists the employees to easily remove the cable harnesses and pre-sort them accordingly without being subjected to unfavourable physical strain.

The compartment boxes are loaded onto the lift tables with forklifts. Centring aids in the form of angular frames are provided on all platforms to assist the forklift drivers to position the boxes. Loading takes place from the platform side without centring aid. Workers on the opposite side pre-pick the material for assembly line production and pack it into the corresponding box compartments.

To make the work steps as efficient as possible, the lift table combination has an automatic control instead of dead man's control. This means that employees do not have to keep the button pressed in to reach the desired lifting position, but can perform other tasks in the meantime.

To provide an impression of how the lift table combination works, we have recorded the video below:

Safety equipment

The lift tables are equipped with a number of safety devices.

For example, the combination has a light curtain; as work is done from both sides on the lift tables and the entire danger zone cannot be properly seen because of the high compartment boxes. If the forklift drives into the area protected by the light curtain, the lifting movements are stopped immediately and the signal lamp on the partition wall lights up yellow. Automatic operation of the lift tables be resumed only after the forklift driver has left the protected area and a worker has pressed one of the two reset buttons.

Another special feature is the interlinking of the emergency stop switches. No matter which emergency stop switch is actuated by the three control panels or the partition wall, it always stops the lifting movement of all lift tables, guaranteeing a quick system shutdown in an emergency situation.

There are also PVC roller screens on the one long side of the platform. A preventive measure against body parts accidentally getting into the scissor area. If a foot should nevertheless ever come into the scissor area, the safety edge under the platforms protects it against being crushed. The two outside steel frame walls prevent moving into the danger zone from the side.