Apart from stationary lift tables, we also manufacture mobile scissor lift tables . When these lift tables need to be moved manually, the question on how easily they can be pushed is especially pertinent for the end user. We will try to provide the answer below.

Rolling friction

By "rolling", a technician means that a wheel rolls over a surface without any simultaneous sliding motion. The force required for the rolling motion is determined by the rolling friction. How high the rolling friction is depends largely on the following two variables:

- The mass to be moved (such as the lift table's dead weight and the load to be transported) and

- the material pairing (e.g. polyamide wheel with concrete hall floor).

Whereas the roughness of the material surfaces is the main factor influencing the frictional resistance in other types of friction, in rolling friction the material pairing itself is the main factor influencing the frictional resistance. This is because the majority of the force to be applied must be used during rolling to overcome the flexing of the wheel. This can be well illustrated if you compare the force required when riding a racing bike with the force required when riding a normal bicycle. The air pressure inside a racing bike tyre is much higher than that inside a simple bicycle tyre. The higher air pressure prevents the wheel from being pressed in less when it makes contact with the road. This reduces the flexing to be done through the deformation of the wheel. This makes it easier to reach higher speeds with the racing bike.

To keep the flexing as low as possible, we mainly use wheels made of polyamide. Compared to rubber tyres, they have a much lower rolling friction coefficient. Only a scissor lift table with steel wheels on guide rails can be moved even more easily.

Our practical example

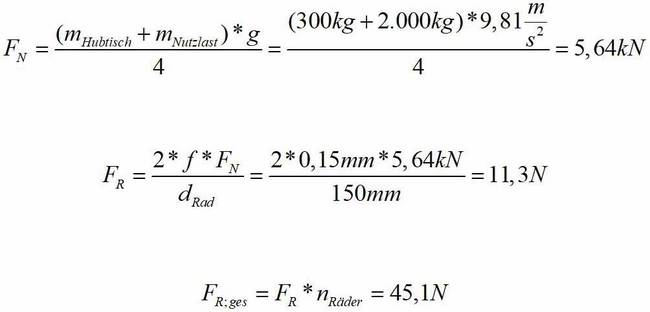

After the theoretical considerations, we want to finally devote ourselves to the practical side of things. We will use a scissor lift table that we have already delivered as an example. The most important key figures of this lift table are:

- Payload = 2,000 kg

- Effective stroke = 800 mm

- Platform dimensions =

1,250 mm x 830 mm - Dead weight = 300 kg

- Wheels used =

polyamide wheels with ball bearings - Wheel diameter = 150 mm

As we could not find a rolling friction coefficient for the "polyamide-concrete" material pairing in the technical literature, we have to use the "rubber-concrete" pairing as a substitute for our example. As already described in the first section, the force required for polyamide wheels is lower than for rubber tyres, so that we get too high a force as a result.

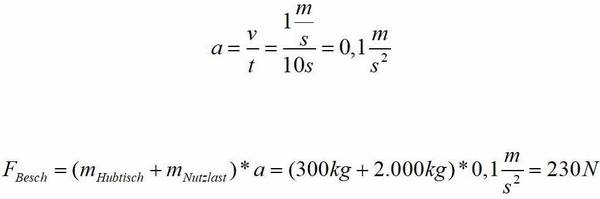

This result shows that the actual pushing of this lift table is not an issue, even payload of 2,000 kg . The main problem with these scissor lift tables, however, is not the force required for pushing, but the force required to accelerate the total mass. Let us assume that we want to push the scissor lift at a speed of about 1 m/s (which corresponds to about 3.5 km/h), and we want to reach this speed after 10 seconds.

The calculation shows that an initial thrust of 230 N is necessary. If you want to accelerate the scissor lift table faster, the effort (or the force required) is correspondingly greater.

The professional association assumes that 95% of all men can apply a maximum thrust of 300 N. On the other hand, only 30% of men can apply a maximum thrust of 600 N (reference to professional association). For prolonged periods of work, the thrust would be 15% of the maximum force (i.e. between 45 and 90 N). Comparing this with our calculation results, it becomes clear that our scissor lift can be accelerated and pushed by one man. However, two people are required for larger lift tables or heavy payloads.

Calculation example vs practice

As shown in our example above, even our sturdy scissor lift tables can be pushed relatively easily, at least in theory. In practical situations, the forces actually occurring can increase considerably if, for example, small stones get in the way .

Sollten Fragen offen sein, freuen wir uns auf einen Anruf oder eine Nachricht von Ihnen. Hier finden Sie den richtigen Ansprechpartner.

Comments (0)

No comments found!