100% quality control

Whether you order one or twenty stationary lift tables is not crucial: Each single lift table is subjected to a strict test.

Enquire about the most common variants

Get a free quote for your stationary lift table in just two steps. Feel free to note any customizations, such as a different payload or dimensions, in the 'Change requests' field:

Installation site requirements

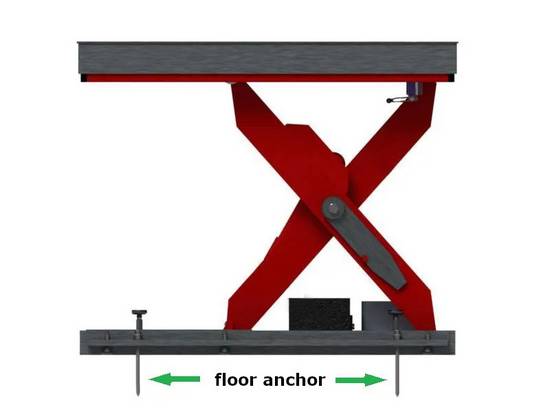

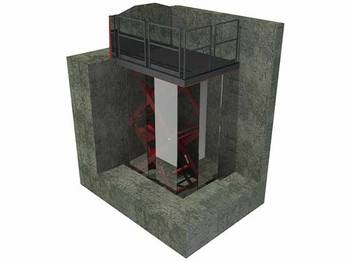

Our stationary lift tables can either be securely bolted directly to the floor or recessed into a pit. The appropriate heavy-duty anchors or adhesive anchors are included in the delivery.

For the safe operation of the lift tables, the following points should be considered when choosing the site:

- The ground must be flat and load-bearing.

- No crushing or shearing points should occur between the lift table, the load, and its surroundings.

As our stationary lift tables come with adjustable feet as a standard feature, minor floor irregularities can be compensated.

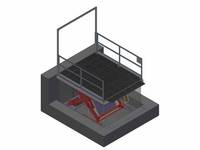

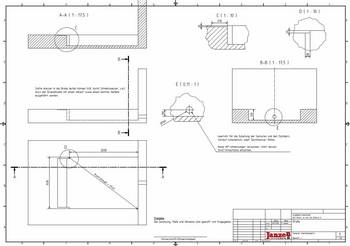

If the scissor lift table is to be installed in a pre-existing pit, we will provide a corresponding pit plan. This will be sent to you along with the approval drawing.

Pit installation vs direct floor mounting

Depending on the purpose and location, there are valid reasons for either pit installation or direct floor mounting of our lift tables. Below, you'll find arguments for each type of installation:

Pit installation is practical when:

- A flush loading and unloading of the lift table is required.

- Space is limited. (We offer the option to design our lift tables as drive-over: When the lift table is in the lowest position, the area can still be used by a forklift or truck.)

Direct floor bolting is suitable when:

- The load is placed using a crane or forklift (e.g., when used as an assembly lift table).

- Height differences in conveyor routes need to be compensated.

In cases where pit installation is not feasible for construction reasons, we can offer two alternative designs: the column lift or the low-profile lift table. Both variations can be loaded using a ramp due to their flat construction.

Furthermore, low-profile lift tables are also available with a U-shaped or E-shaped platform: They are designed to allow flush entry with a hand pallet truck.

If you have any questions about the various design options, we are happy to provide guidance. Feel free to give us a call at +49 5939 96796-90.

Where are stationary lift tables used?

Stationary lift tables seamlessly integrate into operational workflows, offering versatile applications. Whether as a work lift table, a loading lift table for logistical processes, or as system lift tables in production lines, they play crucial roles in leveling height differences, facilitating assembly work, or supporting conveyor loading.

To enhance flexibility regarding the installation location, the drive unit can be installed both inside and outside the lift table.

Do you have any questions or specific requests?

If you haven't found the perfect lift table yet, our team is ready to assist you in finding the right product.

A brief call at +49 5939 96796-90 or an email to info@j-lifte.com is all it takes to get more information.

Frequently asked questions & our answers ...

Where is the headquarters of Janzen Lifttechnik GmbH?

We are at home in the beautiful Emsland, more precisely in Niederlangen a member community of the joint community Lathen directly on the A31 motorway. This means that we are roughly halfway between North Rhine-Westphalia and the North Sea, right on the Dutch border.

Our region is known, among other things, for the various nature reserves, the well-developed cycle paths, the manufacture of cruise ships, as well as the headquarters of various distilleries.

Should you ever come to our region, we look forward to a visit in our plant.

Where are the lift tables and lifts produced?

With us, not only does the final assembly take place in Germany, but we also cover the entire production chain from construction through steel construction to final assembly in our plant in Niederlangen. With us you get a real 'Made in Germany'.

Is the offer aimed only at traders or also at private individuals?

Even if our products are mainly used in an industrial environment, we naturally also offer them to private individuals.

Just give us a call or send us an enquiry and we will be happy to contact you.

Will I receive a drawing before production starts?

In any case. To ensure that you get the product that you really want, we provide you with an approval drawing before production begins. In addition to the actual product, this also includes the installation situation. As the saying goes, a picture is worth a thousand words.

Can I get a CAD model?

After ordering and the design phase, we are pleased to provide you with CAD models. Data exchange is possible in all common formats, including .stp, .dxf, .dwg, etc.

Where can delivery of the products be made?

We produce our lift tables and column lifts in accordance with European standards and guidelines. Accordingly, our sales area is limited to all countries that recognize these standards and guidelines (e.g. the members of the European Union, Switzerland and Australia).

For which countries is the assembly service available?

On request, we assemble our systems throughout Germany, as well as in the neighboring countries of Germany.