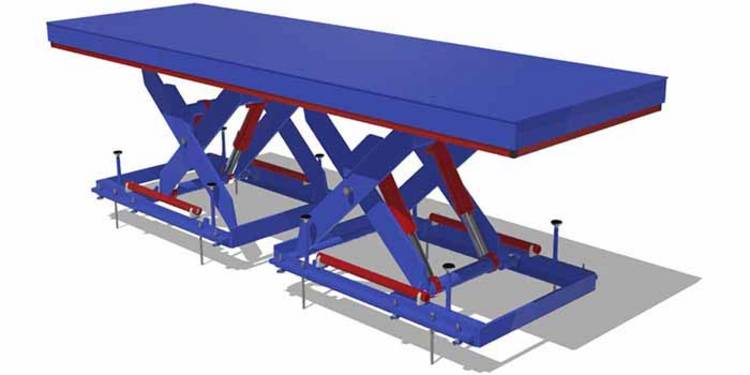

In the woodworking industry, lift tables are often placed in front of a panel saw or similar table saws raise and support long, cut-to-size wooden elements. Because the effective stroke is relatively low in relation to the platform length, a tandem lift table is usually used.

Why doesn’t the tandem lift in the image have a flow divider?

In this case, a flow divider is not necessary to synchronise the scissors despite the two scissor packs, as the tandem lift table is hardly loaded only on the one side with the wood boards. The two shear packs are also positioned quite close to each other. The close mechanical coupling prevents the scissors from operating asynchronously, making a flow divider unnecessary.

What are the special conditions in the wood industry to be taken into account?

As a lot of dust is generally produced in carpentry workshops, a high-pressure filter against fine dust is installed in the pressure line of the hydraulic unit. This is to prevent the oil from silting up and it not only increases the service life of the hydraulic fluid, but also prevents premature wear of the hydraulic components. To make loading and unloading of the wood boards more convenient, the platform cover of the lift table is also made of smooth sheet metal instead of chequer plate. A further advantage is the relatively large platform area. This ensures that bulky loads such as chipboard are handled effectively and safely.

Are the lift tables only available in Germany?

Our scissor lift tables and column lifts are used throughout Germany. And we also supply the Netherlands, Switzerland and Austria. Our sales team will be happy to provide you with more information and advice. We look forward to your contact..