A simple question, with a not so simple answer: It depends. Of course, the price of a scissor lift table largely depends on the exact configuration. Nevertheless, I would like to look at the issue of costs as closely as possible. I will us e a loading lift table as an example.

Cost factors

Costs are incurred during the entire lifecycle of a lift table. From buying it through to its later disposal. In the example of the loading lift table, the acquisition costs of the actual lift table are certainly the biggest factor, while the running costs are relatively low due to the low lifting frequency.

With other types of lift tables, such as plant lift tables, this ratio may change. This is because considerably more strokes are performed during the overall operating time and the fixed costs are therefore better distributed over the number of strokes.

Acquisition costs

Of course, the procurement of the lift table is the first step before it can be used. However, the actual price of the scissor lift table is not only the cost that must be taken into account, but also the structural conditions that must be created.

Apart from the actual lift table, costs may also be incurred for the pit, walls to be built, the power supply to be connected or rooms to be partitioned. The costs for the lift table installation should also not be underestimated, at least when this is not done by your own staff.

Operating costs

In actual operation, most scissor lifts are rather economical. For example, a hydraulic lift table uses most of the energy during lifting, whereas during lowering, usually only a single valve needs to be actuated. If you want to learn more about the advantages and disadvantages of different types of lift tables, I can recommend this series of articles.

In addition to the energy costs, there are of course also costs for the maintenance and servicing of the scissor lift table. This obviously also includes the costs for any wear parts.

Disposal costs

Even the sturdiest product needs be replaced at some point. Therefore, the disposal costs should not be forgotten when making an investment decision. These include particularly all the costs for dismantling, cleaning and removal of the used scissor lift table. The actual disposal can usually be carried out at no cost, as the costs for the disposal of the lubricants and the pressure medium can be covered by the value of the scrap materials.

Costs of a loading lift table

Now we want to bring the dull theory to life with specific facts and figures . As mentioned above, I have chosen a typical loading lift table, which is used relatively often for loading and unloading vehicles as example.

Our lift table has the following key data:

- Platform dimensions:

2,000 mm x 2,500 mm - Effective stroke: 1,400 mm

- Payload: 2,000 kg

- Configuration:

- Loading flaps on a narrow side

- Platform railings on both long sides

- Gantry on one narrow side as fall protection from the top landing

- Corrugated wire-mesh screen as barrier on three sides

- Hot-dip galvanised platform, superstructures and base frame

- Acoustic warning signal during the lifting and lowering process

- Protection class: IP 65

- Electric shut-off valves directly on the cylinders

- Installation situation & intended use:

- The scissor lift table stands in front of a smooth, vertical loading ramp

- It is used both for unloading vehicles and for transport between road level and loading ramp level.

- More information on typical configurations of loading lift tables can be found here; the complete selection can be found here.

Let us now have a look at the individual cost items:

Acquisition costs

The price of the loading lift table is € 10,860 (net). The actual loading ramp is already there, so there are no new costs here, but the pit for the loading lift table still has to be constructed. This costs € 2,750 (net). The 16 A CEE socket is installed by an electrician for € 175 (net). The lift table is installed by the employees of Janzen Lifttechnik GmbH, while the customer's forklift on site can be used for the installation. So the cost to install the lift table is € 1,865 (net).

This is a total acquisition cost of € 15,650 (net).

Operating costs

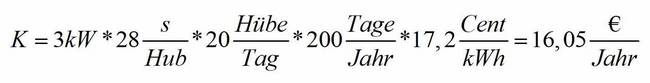

Of course, in this case we use an electrohydraulic lift table. This means that energy costs are mostly incurred during the lifting process. The electrical drive power of our lift table is 3.00 kW. One lifting process takes 28 seconds. At an estimated 200 working days per year with an average of 20 lifting processes generate the following energy costs:

Added to this are the costs for maintenance and servicing. The first maintenance on our lift tables is necessary either after one year or after 50,000 lifting cycles (more information can be found in the article on Maintenance work on the scissor lift table).

Because loading lift tables perform relatively few strokes per day, annual maintenance is sufficient. Travel expenses, working time on site and wear parts bring about additional annual costs of € 635 (net).

Disposal costs

Just like machine tools, lift tables also have to be replaced at some point. Therefore, the disposal costs should be included in the investment decision, even if it may only become due 10, 20 or 30 years down the line.

For dismantling, cleaning and proper disposal of the scissor lift we can reckon with a cost of € 1,595 (net).

Conclusion

Now to add up all the costs. To prepare for the rising price level over the course of the period of use, we take an annual inflation rate of 2% for the disposal and operating costs into account. Regarding the equipment’s shelf-life, we simply orient ourselves to the prescribed service life to determine the depreciation. This is currently 15 years (source: depreciation table for assets of the Federal Ministry of Finance).

Acquisition costs: € 15,650 (net; incl. necessary construction work & installation)

Total operating costs: € 10,399.83 (net; incl. 2% inflation & annual external maintenance)

Total disposal costs: € 2,104.57 (net; incl. 2% inflation)

The loading lift table presented here therefore costs: € 1,876.96 per year or € 0.47 per lifting process. If the lifting frequency is increased to 30 strokes per day, for example, the costs per lifting process are only 0.31€ per lifting process. The low operating costs of lift tables compared other lifting devices are nothing to sneeze at.

Comments (0)

No comments found!