100% quality control

Whether you order one or twenty scissor lift tables is not crucial: Each single lift table is subjected to a strict test.

Enquire about the most common variants

Get a free quote for your loading lift table in just two steps. Feel free to note any customizations, such as a different payload or dimensions, in the 'Change requests' field.

What are loading lift tables?

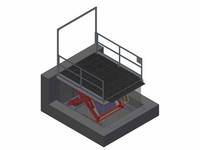

Loading lift tables are specifically designed for use in the logistics sector. They are the ideal solution to facilitate the loading or unloading of vehicles and to effortlessly bridge height differences between a fixed loading dock and the road level.

Thanks to a wide range of accessories, loading lift tables can be flexibly adapted to meet diverse requirements. Their versatility makes them an indispensable tool in the logistics industry.

Overall, loading lift tables ensure a smooth and safe flow of goods. They increase productivity while simultaneously reducing the risk of workplace accidents.

Discover now how you can optimize your logistics processes and save time and costs with our loading lift tables.

Discover the advantages of our loading lifting tables

Speed is of the essence in the logistics sector, requiring reliable and safe loading technology. Moreover, loading tables must be very stable to accommodate docking or the drive-over of trucks & co. We achieve this through the following quality features:

- High safety standards: Manufactured according to DIN EN 1570-1 and the regulations of the Machinery Directive 2006/42/EC, our loading platforms guarantee maximum safety for people and goods. This is particularly important since our lifting platforms also allow the transport of persons.

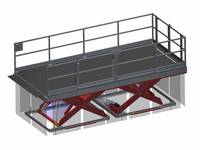

- Robust construction: The use of full steel profiles and heavy cross profiles makes our loading lift tables extremely resistant to torsion and lateral loads. Especially when docking trucks or with uneven load distribution, our products prove their enormous stability.

Moreover, our loading lift tables are often designed for pit installation, as ground-level loading or unloading is required. With the mounting bolts on the subframe that allow optimal force application into the pit, and a reinforced platform, our loading platforms can also be driven over by trucks if necessary. This proves to be particularly practical when space in the hall or yard is limited and every area counts. - Durability: The hot-dip galvanizing of the platform and subframe, as well as electrical components rated IP65, protect our loading lift tables excellently against corrosion and rust. The slip-resistant chequer plate surface on the platform provides additional safety.

- Flexibility: Our extensive product range offers solutions far beyond standard dimensions. As manufacturers, we can produce loading lift tables perfectly tailored to your specific requirements – whether in terms of size, load capacity, or special constructions.

- Easy operation: The simple handling of our loading lift tables not only reduces the risk of workplace accidents but also saves time during loading and unloading.

Upon request, our assembly team can take care of the on-site installation. Benefit from a quick and professional execution.

Flexibility through individual customization options

Our product range is complemented by a wide array of lift table accessories, offering ample room for customization. The accessories enable a modular expansion of your loading lift table and can be perfectly tailored to your specific needs. Typical features include:

Segmented loading flaps

With the help of loading flaps, the gap between the lift table and the vehicle is bridged. Choose between manual or powered loading flaps – the latter also act as an effective roll-off prevention and protect against falling rolling loads.

Underrun protection

To ensure that no individuals can enter the danger zone beneath the lift table, our product portfolio includes the appropriate underrun protection. Various options are available, including corrugated wire mesh, PVC roll curtain or bellows. More information on each protective type can be found in our article:

To ensure safety around the lift table, we offer various underrun protection options, including wire mesh, PVC roll-up curtains, or bellows. These measures prevent people from entering the hazardous area under the lift table. For more information on the respective types of protection, refer to our article: 'Underrun protection for scissor lift tables'.

Hot-dip galvanization

For outdoor use, we subject the subframe, platform, and all structures to hot-dip galvanization. Together with the IP65 protection class, this ensures the durability and reliability of your lift table, even in adverse weather conditions.

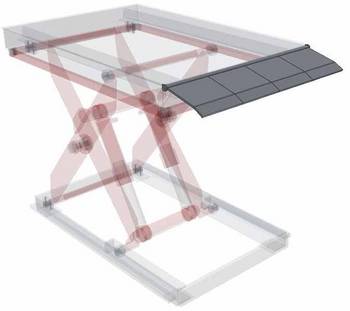

Reinforced platform and mounting bolts

Especially for cases where your loading lift table is to be driven over by a truck, we offer a reinforced platform and additional mounting bolts. These constructions ensure optimal force introduction and the necessary stability to withstand the stresses of a truck drive-over.

Advantages of segmented loading flaps

Since loading lift tables are often used for loading and unloading trucks, the standard dimensions are frequently based on semi-trailers. To still enable easy adjustment to different vehicle widths, we rely on segmented loading flaps.

Discover in our following video how our segmented loading flaps work in practice and how they facilitate the loading and unloading process through their adaptability:

Loading lift table - the ramp alternative

Many are familiar with the challenge of pushing heavy hand lift trucks or mesh container up a ramp. Typically, there are two designs for ramps: either they are flat and relatively long, or they are short and extremely steep. Pushing the load up can become quite exhausting over time.

Discover a more comfortable solution – our loading lift tables. They offer an efficient, ergonomic, and space-saving alternative to conventional ramps. With a variety of sizes and load capacities, they perfectly adapt to your individual needs. Whether in the warehouse, production area, or for loading and unloading vehicles, our loading lift tables optimize your work processes and reduce physical exertion.

Do you have specific questions or need advice on our loading lift tables? Our team is here to help you find the optimal solution for your requirements. Do not hesitate to get in touch.

Our freestanding loading lift table model

Watch the following video to gain insight into how our freestanding loading lift table model operates within the interior of a warehouse:

Discover our classic loading lift table

Explore our classic loading lift table – a model of robustness and efficiency within our product line. This lift table combines a high load capacity and effortless height adjustment with comprehensive safety features:

- Dimensions & capacity: With a platform length of 2,500 mm and a load capacity of 2,000 kg, this lift table is equipped for a wide range of loading tasks. It completes a lift of 1,200 mm in just 30 seconds. Due to a construction height of 310 mm without railings, installation in a pit is advisable, allowing for transport operations from ground level as well.

- Adaptability: The segmented loading flaps increase the flexibility of the scissor lift platform. They allow for easy adjustment to a wide range of vehicle widths – from sprinter vans to trucks.

- Safety: Equipped with side platform railings, acoustic signals during lifting and lowering movements, and a wire mesh underrun protection, this lift table ensures maximum safety for operators and bystanders. The portal on the platform additionally serves as protection against fall hazards.

- Durability & reliability: The hot-dip galvanized finish of the platform and subframe indicates that this lift table is specifically designed for outdoor use. The electrical components are rated IP65, ensuring reliable operation even in moist environmental conditions.

Your reliable partner for efficient loading operations

In the logistics industry, efficient and smooth processes are crucial. As an experienced lift table manufacturer, we have successfully implemented a wide range of customer requirements to enable fast and safe goods handling. One example of our work is the installation at an airport, reported in an article by BERNSTEIN AG titled 'Reaching high at the airport - not only on the runway'.

Convince yourself of our quality and flexibility. A first impression of our capability is conveyed through numerous references. Discover how we create individual solutions that are precisely tailored to the needs of each project.

Contact us for special requests. Do you have special requirements or questions about our loading lift tables or the maintenance of your equipment? We are here for you. Reach us by phone at +49 5939 96796-90 or send us an email at info@j-lifte.com.

Simplified project planning with our tender templates. We know that loading lift tables are often an important part of tenders. To make your project planning easier, we provide tender templates for download.

Frequently asked questions & our answers ...

Where is the headquarters of Janzen Lifttechnik GmbH?

We are at home in the beautiful Emsland, more precisely in Niederlangen a member community of the joint community Lathen directly on the A31 motorway. This means that we are roughly halfway between North Rhine-Westphalia and the North Sea, right on the Dutch border.

Our region is known, among other things, for the various nature reserves, the well-developed cycle paths, the manufacture of cruise ships, as well as the headquarters of various distilleries.

Should you ever come to our region, we look forward to a visit in our plant.

Where are the lift tables and lifts produced?

With us, not only does the final assembly take place in Germany, but we also cover the entire production chain from construction through steel construction to final assembly in our plant in Niederlangen. With us you get a real 'Made in Germany'.

Is the offer aimed only at traders or also at private individuals?

Even if our products are mainly used in an industrial environment, we naturally also offer them to private individuals.

Just give us a call or send us an enquiry and we will be happy to contact you.

Will I receive a drawing before production starts?

In any case. To ensure that you get the product that you really want, we provide you with an approval drawing before production begins. In addition to the actual product, this also includes the installation situation. As the saying goes, a picture is worth a thousand words.

Can I get a CAD model?

After ordering and the design phase, we are pleased to provide you with CAD models. Data exchange is possible in all common formats, including .stp, .dxf, .dwg, etc.

Where can delivery of the products be made?

We produce our lift tables and column lifts in accordance with European standards and guidelines. Accordingly, our sales area is limited to all countries that recognize these standards and guidelines (e.g. the members of the European Union, Switzerland and Australia).

For which countries is the assembly service available?

On request, we assemble our systems throughout Germany, as well as in the neighboring countries of Germany.