Quick quotations

On average, our customers receive their personalized quote within just 1.8 working days, including the clarification of any potential queries.

Enquire about the most common variants, simply and without obligation

Get a free quote for your goods lift in just two steps. Feel free to note any customizations, such as a different payload or dimensions, in the 'Change requests' field:

Inhaltsverzeichnis

[ein-/ausklappen]

- 1. What is a goods lift?

- 2. Which construction types are common for goods lifts?

- 3. Which goods lift is the best?

- 4. How much does a goods lift cost?

- 5. What are the advantages of goods lifts without passenger transport?

- 6. Applications of goods lifts

- 7. How much space does a goods lift require?

- 8. How often does a goods lift need to be inspected?

- 9. Which safety devices does the goods lift have?

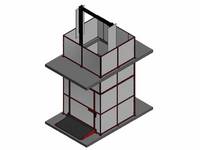

Goods lifts are specially designed lifts that enable efficient transportation of goods and materials between different floors in buildings or industrial facilities.

A goods lift is a freight elevator without passenger transport.

This means individuals can enter the cabin for loading and unloading purposes but are not allowed to ride along. This restriction allows for the omission of certain safety features. For example, cabin doors and recurring inspections by certified inspection agencies like TÜV, DEKRA, etc., are not necessary, saving costs. Compared to passenger elevators, goods lifts typically have a higher load capacity and a larger usable area to accommodate bulky and heavy loads.

Key features of our goods lifts include:

- High load capacity: Our hydraulic lifts can move several tons of weight.

- Robust construction: Our goods lifts are designed to operate reliably and safely for many years.

- Customizability: Thanks to our in-house design and manufacturing, we can tailor the goods lift to your specific requirements. Dimensions, load capacities, and features can be customized to meet your needs.

- Efficiency: The use of our goods lifts allows for fast and efficient transportation of goods and materials between different floors, saving time and resources.

- Space pptimization: Goods lifts open up new levels, expanding available storage and workspace. Additionally, they require less space compared to alternatives such as ramps.

Overall, due to their design and purpose, goods lifts represent a cost-effective solution for quick and secure handling of goods.

Similar to traditional passenger elevators, freight elevators without passenger transport are available in various construction types. Here, we would like to briefly discuss the most common construction types and applications.

A small note in advance: Our company exclusively manufactures goods lifts based on column lifts or scissor lift tables.

Winding drum elevator

The winding drum elevator can be considered a classic in elevator technology. In this design, the cabin is suspended by multiple wire ropes. The cabin is lifted or lowered by winding and unwinding the wire ropes on a drum. The guidance of the cabin is achieved through lateral rails.

Since the wire ropes of the winding drum elevator are always under tension, there is no risk of bending. Therefore, this design is particularly suitable for achieving greater lifting heights.

Column lift

Now, we come to the first type of construction that our company manufactures. Similar to winding drum elevators, the cabin is suspended by multiple wire ropes. However, the upward and downward movement is achieved through the extension and retraction of hydraulic cylinders. The guidance, again similar to winding drum elevators, is provided by lateral rails.

As the hydraulic cylinder in this design is used under pressure, the issue of buckling needs to be considered. For this reason, the column lift is well-suited for achieving up to three stops.

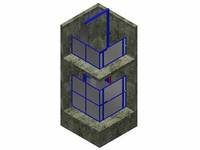

Scissor lift

In this design, the elevator cabin is mounted on the platform of a scissor lift table. The extension and retraction of the scissor achieve the upward or downward movement of the goods lift. No lateral guide rails need to be installed as the guidance of the cabin is implemented by the scissor mechanism itself.

Whether this construction type is suitable depends primarily on the desired lifting height and the required cabin size. Especially at large lifting heights, the weight of the lifting mechanism quickly exceeds the transport load, making this construction type more suitable for achieving two to three stops.

Traction drive lift

This design was developed to improve the energy efficiency of electromechanical elevator systems. A counterweight within the shaft moves in the opposite direction to the cabin's travel direction. The height of the counterweight is adjusted to the cabin's weight and the anticipated average revenue load. The counter movement of the weight allows for a smaller drive, thereby reducing the energy consumption of the elevator system. The overall structure is similar to a winding drum elevator, with guidance provided by laterally mounted guide elements.

Due to its higher energy efficiency, this construction type has almost entirely displaced the classic winding drum elevator.

Plunger lift (direct hydraulic lift)

In this design, the cabin of the goods lift is directly mounted on a hydraulic cylinder. The lifting and lowering movement of the cabin is achieved by extending and retracting the cylinder. To realize greater lifting heights without the need for a correspondingly deep pit, telescopic cylinders are typically used.

As the hydraulic cylinder in this design is used under pressure, the issue of buckling needs to be considered. In practice, this often leads to hydraulic cylinders with relatively large diameters.

Given the variety of different construction types, the question arises as to which type of elevator is the best. Unfortunately, there is no one-size-fits-all answer. To help you find the most suitable construction type for your needs, we have compiled some key points below.

Selection criteria for the appropriate elevator type include:

- The desired lifting height or the number of floors to be reached.

- The ratio of lifting height to platform dimensions.

- The placement of access doors at the stops.

- The frequency of use of the elevator system.

If a goods lift based on a scissor lift table or a column lift is an interesting alternative for 2-3 floors, a traction drive elevator becomes nearly indispensable for 10 floors.

However, even when only two to three floors need to be reached, the traction drive elevator can be the better choice. The lower maintenance effort and lower acquisition costs of the hydraulic goods lift are offset by the higher energy consumption at a high frequency of use, approximately 150 cycles/hour or more (see our article 'Hydraulic elevator vs. traction drive elevator: Which elevator drive ist suitable?').

The decision between a column lift or a scissor lift table as the basis for your goods lift depends, in turn, on the ratio of platform length to lifting height or whether a diagonal arrangement of the doors at the stops is desired.

As you can see, the decision for or against a construction type involves multiple influencing factors that are not clearly delineated. In case of doubt, feel free to contact us. We provide comprehensive advice on the elevator type that suits your needs. You can reach us at the phone number +49 5939 96796-90 or via email at info@j-lifte.com.

Undoubtedly, costs play a crucial role in the consideration for or against a goods lift. However, especially in the case of custom manufacturing of goods lifts, there is no no one-size-fits-all answer to the question of price.

Nevertheless, we would like to provide you with an approximate idea of the costs by considering the factors that significantly impact the acquisition expenses and providing a concrete example.

What influences the acquisition costs?

Let's begin with the influencing factors. Crucial for the purchase price of a goods lift without passenger transport are, among others, the following factors:

- The size of the cabin.

- The desired load capacity.

- The number of floors to be reached and the associated lifting height.

- The installation location of the elevator system.

- The number of required extras (such as ramps, enclosures, etc.).

- Whether the goods lift should be located indoors or outdoors.

A specific example

A goods lift is often used to transport Euro pallets between two floors. Therefore, let's consider a required platform size of 1.5 m x 1 m, a load capacity of 1,500 kg, and a lifting height of 3 m. If this elevator operates within an existing shaft, and only two safety interlocks need to be supplied by us to the actual goods lift, the estimated cost would range between €20,000 and €30,000.

Ongoing operating costs

In addition to the acquisition costs, the ongoing operating costs of the elevator system are, of course, relevant. In this regard, our goods lifts have an advantage: they do not require annual inspections by an external expert. Therefore, in addition to energy costs for the continuous operation of the system, only maintenance and repair costs are incurred.

If you would like to get a sense of the magnitude of these cost items, we recommend taking a look at our article 'How much does a lift table cost?'. There, we have examined the cost components for a hydraulic scissor lift table.

In addition to the advantages that a goods lifts generally offers, such as the safe and fast transport of goods, there are additional benefits from foregoing passenger transport. Essentially, these can be summarized in one point: The elevator variant without passenger transport is more cost-effective compared to other types of elevators.

A goods lift without passenger transport is not a system requiring surveillance; instead, it is considered a regular machine. Therefore, for the necessary inspections on the goods elevator, there is no need to commission an approved monitoring authority (TÜV, DEKRA, etc.). The task can be carried out by an elevator service, the lift manufacturer, or, with the appropriate qualifications, an in-house employee.

During manufacturing, goods lifts without passenger transport offer several advantages. Among other things, the provision for self-rescue and external rescue out of the cabin can be omitted. However, the more crucial aspect is that goods lifts without passenger transport do not require type examination. This allows for flexible adaptation to your installation situation without initiating an elaborate test procedure for individual elevator systems.

As goods lifts without passenger transport are considered regular machines, there is also no requirement for registration with the trade supervisory centre.

After exploring the definition and various types of goods lifts, the question arises: Where and for what purposes are goods lifts used?

The answer is: Goods lifts are used whenever goods and loads need to be transported between different floors, both indoors and outdoors.

However, this general answer indicates that there is no one standard transport task. The application areas are as diverse as the design possibilities of the elevators themselves:

Our goods lifts are needed in production facilities, warehouses, laundry facilities, swimming pools, car dealerships, as well as in nursing homes and hospitals. If we were to describe a classic use case, it would probably be the deployment in an industrial company with production or storage space distributed across two floors.

As individual as the design possibilities of our goods lifts are, so is their space requirement. The required footprint depends, among other things, on the desired platform size and the building class of the elevator. Let's take a closer look at the platform size first.

How large should the platform be for transporting an europallet?

In logistics, the europallet is an indispensable standardized load carrier. Therefore, it's not surprising that we are often asked the question: How large must the platform of a goods lift be at a minimum to move an europallet between floors?

As a first reference point, the size of the europallet itself serves: With a length of 1,200 mm and a width of 800 mm, a platform size of 1,400 mm x 1,000 mm is sufficient for a single europallet. These dimensions already take into account some space for maneuvering and for not perfectly stacked europallets.

If, in addition to the europallet, a manual lift truck is to be transported, this platform length is no longer sufficient. In this case, we recommend increasing the cabin length to at least 1,500 mm, preferably 1,600 mm.

If the goods lift is also a through-loader, the platform dimensions should be adjusted again. The platform length should be increased to at least 1,700 mm, and the platform width should be increased to at least 1,500 mm to be able to move the manual lift truck at all.

| Situation | Recommended minimum platform size |

|---|---|

| Transport of an europallet | 1,400 mm x 1,000 mm |

| Transport of an europallet + manual lift truck | 1,500 mm x 1,000 mm |

| Transport of an europallet + manual lift truck + elevator as a through-loader | 1,700 mm x 1,500 mm |

As mentioned earlier, the dimensions provided are the recommended minimum dimensions. Naturally, we are capable of realizing larger goods lifts according to your individual requirements.

What dimension is added to the actual platform size?

The definitive answer to this question is unfortunately only possible after the completion of the design phase. Nevertheless, for an initial rough room planning, you can temporarily refer to the following values:

If the goods lift is a two-column lift, approximately 800 mm should be added to the platform width to account for the space needed for the two lifting columns.

If a scissor lift table is used as the basis for the goods lift, it is not necessarily required to calculate an allowance, as the entire technology is located beneath the lift table platform. However, it might be advisable to provide a slightly longer platform to save on certain scissor packages.

In addition, the required footprint for the elevator shaft should be considered. If the elevator enclosure is done by us, 100 mm can be added for each side to be enclosed.

For a typical goods lift as a column lift with a platform size of 1,500 mm x 1,000 mm, the total footprint would be approximately 1,700 mm x 1,800 mm with enclosure on all four sides using one of our shafts.

And how large is the pit?

In addition to the footprint, the required pit depth is, of course, of interest. Unfortunately, we cannot provide standard dimensions here, as the necessary pit depth depends on numerous factors (platform size, effective stroke, elevator design, load capacity, etc.).

In the goods lifts we have installed so far, the pit depth has varied between 0 mm and 2,000 mm. Wait, a pit depth of 0 mm? No, this is not a typing error. When a column lift is used as the basis for the goods lift, the pit at the lower stop can often be replaced by a small ramp upon request.

Is a separate machine room required?

A separate machine room is not required for our goods lifts. However, we recommend not integrating the hydraulic unit and control into the shaft but placing them externally. Suitable spaces for this purpose are areas that would otherwise remain unused. Good examples include spaces beneath a stairway or directly next to or behind the shaft.

What is the maximum cabin size that can be implemented?

The largest platform length we have implemented so far is just under 9,500 mm, while the largest platform width is 3,500 mm. As you can see, there is a lot of flexibility for individual design possibilities. We look forward to designing and manufacturing a customized platform size for you.

Those who have already read our article 'Does every elevator have to be inspected by TÜV?' will not learn anything new now: Our goods lifts are not subject to inspection by an approved inspection agency such as TÜV or DEKRA.

Inspection by an external expert is only required if the goods lift falls under systems subject to monitoring. This would be the case, for example, if not only goods but also passengers were transported. For this reason, we exclusively offer our goods lifts without passenger transport. Additionally, the maximum travel speed of our elevators is limited. Through these measures, the elevator operator avoids the annual inspection by an external expert and the associated fees.

If, however, you still desire an expert inspection upon the elevator's commissioning, we can gladly organize this for you.

The fact that no inspection by an approved inspection agency is required, does not mean that no inspection at all is necessary. If the goods lift is, for example, used in a commercial environment, it is to be treated like a regular working appliance. Accordingly, an annual inspection in accordance with accident prevention regulations and the industrial safety ordinance is essential. These inspections can be conducted by a qualified person. Thus, an inspection by your own appropriately qualified personnel is possible, or you can have these tasks performed by us as part of the annual maintenance.

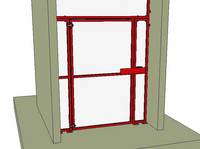

With the purchase of a goods lift, our goal is not only to ensure fast goods transport between two floors but also to prioritize the safety of the operating personnel and surrounding individuals. Therefore, our goods lifts are equipped with a variety of safety devices:

Enclosure of the danger zone

One of the most effective safety measures is to keep people out of the danger zone. Therefore, except for so-called deadman and underground lifts, all our goods lifts have an enclosure at the stops.

Each stopping point, in turn, has a door that can only open when the platform of the goods lift is in the respective floor. This ensures that people cannot fall from the upper stop or enter the danger zone below the raised platform.

For more detailed information on the various types of shafts, we recommend our article 'Choosing the right enclosure for your elevator'. At this point, we would like to briefly mention that various construction types are possible – ranging from simple concrete shafts or masonry shafts to shafts in timber frame construction, steel frameworks, or enclosures made of sandwich panels.

Special attention is given to the doors of the stopping points. Here, either simple steel frame doors from our own production or standard elevator doors are used. Both variants are secured by an electromechanical safety interlock. This ensures that the door is not only closed but also securely locked. Opening the door at the stopping point is only possible when the platform is in the correct position. However, in case of a malfunction, the safety interlock can be manually released, allowing access to the shaft. The unlocking is registered by the elevator control, ensuring that any movements of the cabin are excluded.

Overload protection

Of course, it must also be ensured that the goods lift is not overloaded. Therefore, our hydraulic lifts are equipped with two safety devices: a pressure limiting valve and a pressure switch.

The pressure switch determines the current system pressure and communicates it to the elevator control. The elevator control checks whether the system pressure is within the permissible range or if an overload warning needs to be issued.

In contrast, the pressure limiting valve works without electronic components. A spring mechanism ensures that if the system pressure is too high, oil is drained into the tank, preventing the platform from rising.

Speed limitation

The goods lift must not reach an impermissibly high speed. Securing against excessive lifting speed is relatively simple for a hydraulic lift table: The maximum flow rate of the hydraulic unit determines the maximum travel speed during the lifting process. Proper dimensioning of the drive ensures that the maximum permissible speed is not exceeded.

The lowering process must also occur in a controlled manner. This is achieved by limiting the amount of oil flowing back into the tank. An appropriate lowering control valve ensures that the desired speed is not exceeded during the lowering process.

Safeguarding against a cabin crash

The fall protection can be considered as a continuation of the speed limitation point. Here, we also want to prevent the exceeding of a maximum lowering speed. We rely on a two-stage safety system in this regard.

We install unlockable check valves directly on the hydraulic cylinders of the goods lift. These valves seal off the hydraulic line directly at the cylinders in the event of a hose break to prevent the cabin from dropping. The opening of the valves requires that all access doors are closed or locked, and a lowering command has been issued to the control system.

However, what happens if a hydraulic hose ruptures while the cabin is already in the descent? To prevent impact at the lower stop, we additionally rely on lowering brake valves. These valves are not intended to limit the normal travel speed but act as safety valves installed directly on the hydraulic cylinders before the check valves.

Thus, even during a descent with a complete hose rupture, it is ensured that the cabin arrives at the lower stop maximum with rated speed (or not at all if the emergency stop button has been pressed, thereby closing the check valves).

Maintenance stands

In regular operation, it is strictly prohibited to be underneath the platform – for this reason, this area is enclosed by us. However, there are situations, such as maintenance or repair work, where it may be necessary to enter the hazard zone beneath the raised platform.

For this reason, all our goods lifts are equipped with maintenance stands. If it becomes necessary to enter the hazard zone, the appropriate maintenance stands must be set in advance, ensuring that there is always enough space between the platform and the floor in case of an emergency for self-protection.

The process is quite simple: Insert the maintenance stands over the corresponding bolts, then lower the platform onto the maintenance stands, and proceed with the necessary work at your own pace.

If needed - floor locks or hydraulic locking bolts

A somewhat unusual safety feature includes hydraulic locking bolts for the upper stop. Typically, a goods lift designed solely for transporting goods is engineered to handle the desired rated load (including appropriate safety factors). However, what if, for instance, you need to transport a weight of 1,000 kg, and for loading, an electric high-lift truck is required, which also weighs 1,000 kg?

Solution option #1: You design the goods lift for a total weight of 2,000 kg. However, this means that the mechanics for the lifting process are oversized.

Solution option #2: Hydraulic locking bolts are used at the respective stops to lock the platform. This way, during loading and unloading processes, the load is no longer supported by the lifting mechanism but is directly transferred into the shaft walls.

How long does it usually take until I receive a quote?

On average, our customers receive their quotes within 1.8 business days, including any possible follow-up questions.

How do I get to my goods lift?

The way to your goods lift is relatively straightforward. It starts with an enquiry so that we can determine the appropriate solution for you. There are various ways to submit your enquiry:

- Perhaps one of the variants shown above suits your needs → If so, this is likely the easiest way to receive a quote. Of course, you can specify any desired variations during the completion of the enquiry form.

- Or you require a highly customized solution: In this case, either a personal conversation over the phone at +49 5939 96796-90 or our more comprehensive enquiry form for a goods lift would be suitable.

- If you have already compiled all requirements in a document, feel free to send it to us via email at info@j-lifte.com.

After receiving your enquiry, we will send you a detailed quote. If you find the quote satisfactory, we look forward to receiving your order.

You don't need to worry about potentially ordering something incorrect. Before the start of production, you will receive a working plan from us, depicting not only the goods lift but also the installation situation, shaft, or pit. This way, you always know what you are getting.

Once you have given us the production approval, we will commence the production of your custom goods lift and will contact you again approximately two to three weeks before the installation date.

During this time, we will address any remaining organizational matters, such as on-site contacts and the necessary registration of our personnel.

Speaking of installation: This will be carried out by our own employees, ensuring that the installers have excellent product knowledge. Your goods lift will be installed in no time.

The installation duration typically ranges from one to three business days, depending on factors such as whether the complete enclosure is also supplied by us. This ensures that we leave your construction site quickly, minimizing disruption to your operations.

How long is the warranty period for the goods lift?

Legally, you are entitled to a warranty period of 12 months. However, as we produce high-quality and durable freight elevators, we extend this period as a standard practice to 24 months.

When entering into a maintenance contract, we extend the warranty period to 60 months.

How reliable is the supply of spare parts?

This aspect is likely one of the biggest advantages of our products. While it may be uncommon in the elevator industry, we earn our revenue through the sale and installation of new goods lifts, not through service contracts and the associated supply of spare parts.

That's why we use widely available standard components in our goods lifts. We control the various stops of the elevator using common sensors found in the market. The evaluation is not done through a manufacturer-specific board but rather through a programmable logic controller, rat any well-stocked electrical wholesaler.

This means you are not solely reliant on us for spare parts. If you prefer, you can also obtain the necessary replacement part from us. All standard components are in stock with us.

What is the maximum speed for a goods lift without passenger transport?

Our goods lifts have a maximum travel speed of 150 mm/s. Now, the question naturally arises: How did we arrive at this particular value?

It's for the same reason that we exclusively offer goods lifts without passenger transport. Higher travel speeds would subject the goods lift to the lifts directive, along with the associated inspection obligations. This means you would need to have the goods lift inspected by an external expert every year, not just during the commissioning of the elevator system.

When does my employer need to install a goods lift?

This question can be answered easily: never. There is no legal obligation for employers to install goods lifts.

The relevance of a goods lift without passenger transport is primarily determined by the specific use case. If loads of more than 30 kilograms need to be regularly moved to another floor, it is likely not sustainable for any employee in the long run. Additionally, no employer is interested in having their employees suffer physical discomfort from lifting heavy loads.

Who is authorized to perform maintenance on the goods lift?

The maintenance on our goods lifts may be carried out by an expert. Therefore, it can be done internally, provided there is sufficiently qualified personnel, by an external specialist company, or, of course, by us.

What load capacities are possible for a goods lift?

Load capacities typically range from 500 kg to 4,000 kg. However, we also implement custom constructions with a load capacity of up to 10,000 kg.

The load capacity that we can ultimately implement depends on the desired platform dimensions and the required lifting height.

Do you offer tender documents for download?

At the following link you can find tender templates for download.

Is a pit absolutely necessary

In not every case is a pit necessary for the elevator. This depends on the choice of the lifting mechanism. If a scissor lift table is used as the base, a pit must be constructed. However, if a column lift is used, a pit can usually be omitted.

Which option is most effective for you depends on various factors (e.g., whether a corner loading is desired or the ratio of platform length to lifting height). We would be happy to advise you to find the best solution for your needs.

Is a shaft provided by the client required?

In this case, everything is possible, but nothing is mandatory. We can design our elevator to be integrated into your existing shaft. Alternatively, we can also deliver and install a suitable self-supporting shaft for you.

How long do I have to wait for my elevator?

Unfortunately, this question cannot be answered universally and depends on the current order situation. Typically, one can expect a delivery time of 6 months, with on-site installation usually completed within 3 days.

Foldable elevator doors

How to combine a large access opening for a goods lift with a small anteroom? One possible solution: foldable elevator doors. The additional hinges allow the door panels to be folded together in a space-saving manner, while maintaining the large opening for loading and unloading.

Free-standing column lift

When large lifting heights need to be achieved with small platform dimensions or when no pit can be installed, our column lift is a great choice. One advantage is its excellent adaptability to structural conditions.

Triple scissor - all good things come in threes!

When the platform length limits the scissor length of the lift table and the desired lifting height cannot be achieved, two solutions are available: the use of our column lift or stacking scissors. A customer opted for the latter, as demonstrated in the following video. The desired lifting height is achieved by stacking three sets of scissor packs. For more information on possible lifting heights, we recommend checking out our article 'How high can a lift table lift?'.

Column lift with true size

When a pit is not feasible, our column lift is the right choice. In the following video, you can see an example of a column lift with a large platform serving as a goods lift. For more information, please visit the following link: 'Column lift with true size'.

- The basis - scissor lifts tables and column lifts

- Use of lift tables in extreme temperatures

- Sealing an underground lift

- Forget error codes!

- Hydraulic elevator vs. traction drive elevator: Which elevator drive is suitable?

- Using a lift table as a goods lift

- Does every lift need to be inspected by Technical Inspection Authority like TÜV?

- Safety devices on the lift table: hydraulic valves

- When can an enclosure be omitted for elevators?

- The suitable enclosure for your elevator!

- Avoidable mistakes in project execution

- How high can a lift table lift?

- What requirements must an elevator shaft meet?

- What hydraulic oils are used in scissor lift tables?

- The most important guidelines & standards for scissor lift tables

- How a scissor lift table is made …

![[Translate to English:] CAD-Modell eines vereinfachten Güteraufzuges [Translate to English:] CAD-Modell eines vereinfachten Güteraufzuges](/fileadmin/_processed_/1/9/csm_cad-modell-eines-vereinfachten-gueteraufzueges_4a53b65b23.jpg)