The headline is rather confusing. However, this question needs to be taken quite seriously in both scissor lift tables and column lifts . Depending on how the load is distributed on the lift table, it is possible that a standard lift table designed for 1,000 kg can only carry 300 kg or less. In this short article we will clarify which load capacity is guaranteed ...

What is the guaranteed payload of a lift table?

EN 1570-1 is the most important standard for lift tables and also regulates what the scissor lift should at least be able to carry. The standard specifies three requirements for this:

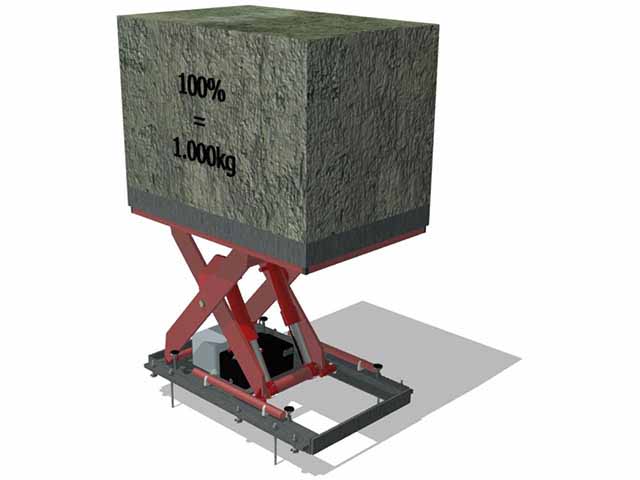

1. The lift table must have the specified load capacity when the load covers the entire surface area .

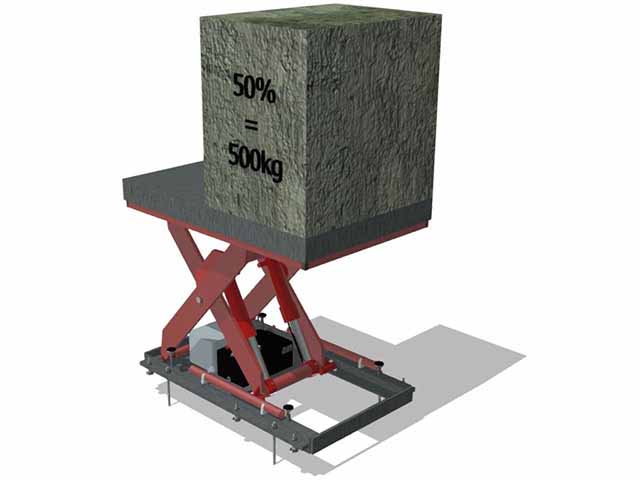

2. If the load covers only half the length of the platform of the lift table, it must still be able to carry half the specified payload. So 500 kg in our example.

3. If the load covers only half the width of the platform of the lift table, it must still be able to carry a third of the specified payload. In our example, this means about 330 kg.

If it is known that the load will not be evenly spread over the entire platform, but will cover only one half of the platform surface, you can already use this knowledge to select a suitable standard lift table . If you want to lift 1,000 kg with an uneven load distribution, you can choose either a standard lift table with 2,000 kg or a standard lift table with 3,000 kg load capacity.

But what do you do if the load distributions listed in the standard specifications do not match the application? If you want to be on the safe side in this case, you should discuss the force transmission directly with the lift table manufacturer . If the manufacturer has his own design department, he will also be able to select and supply the matching lift table.

Why doesn’t the lift table carry the specified payload when the load is unevenly distributed?

The reason is the interaction of force and lever arm. Depending on where the load is placed on the platform, this leads to a different load on the scissor bars of the lift table. I would like to explain this using two very simplified examples:

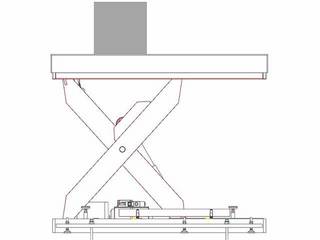

Example 1 – The load is centred between the fixed and non-locating bearing

In this example, we have placed the load on the lift table so that it is exactly centred between the non-locating and fixed bearings of the lift table. This ensures that the load is carried equally by the non-locating and fixed bearing sides. The scissor lift table is optimally loaded and its maximum load capacity is available.

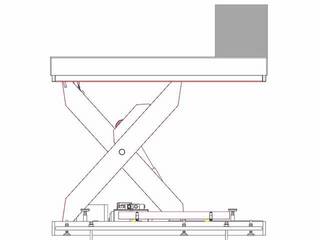

Example 2 – The load is placed on the platform edge

If this sketch is compared with the sketch from the first example, it quickly becomes clear that in this case the load is not carried equally by the fixed and non-locating bearing sides. Instead, the non-locating bearing has to support much greater forces. The fixed bearing side of the lift table hardly helps to lift the load. This means that although the same payload is lifted in both cases, the non-locating bearing side is subjected to twice as much load. This hopefully also shows that the load specification on a scissor lift table cannot apply to every load case.

Comments (0)

No comments found!